ILsa Diagnostics a conçu des instruments et des solutions pour rendre des résultats plus fiables, toujours plus performants dans le but d’améliorer la santé humaine pour le dépistage du cancer du col de l’uterus en cytologie et pour les bio-bank et centres de transfusion sanguine pour la conservation des échantillons sanguins et la gestion de leurs sérothèques.

Tout d’abord, la qualité de l’étalement sur lames des échantillons prélevés :

• Pas d’amas de cellules, cellules bien séparées et sans déformation, homogène grâce à la double centrifugation contrôlée :

• Spot monocouche reproductible (concentration cellulaire identique sur la lame quelle que soit la concentration de l’échantillon.

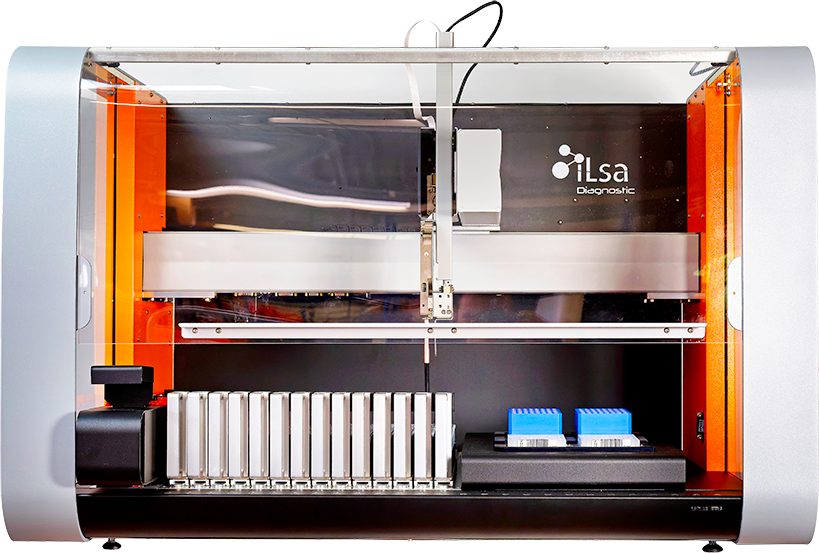

Dernier né de la gamme des produits iLsa Diagnostics.

Un instrument compact avec une configuration modulaire et évolutive pour s’adapter au nombre de lames / jour. La centrifugation intégrée des flacons échantillon à fond coniques permet de concentrer les prélèvements pour traiter automatiquement tout type de prélèvement : Gyn et non Gyn (Thyroïde, Urine, LCR …).

Très haute cadence.

Ouverture et fermeture automatiques des flacons échantillon.

L’IDC 20 automatise les opérations d’étalement, sans aucun risque d’erreur.

Grâce à une double centrifugation et à une lecture de turbidité intégrée l’iDC 20 permet un étalement homogène, monocouche et reproductible.

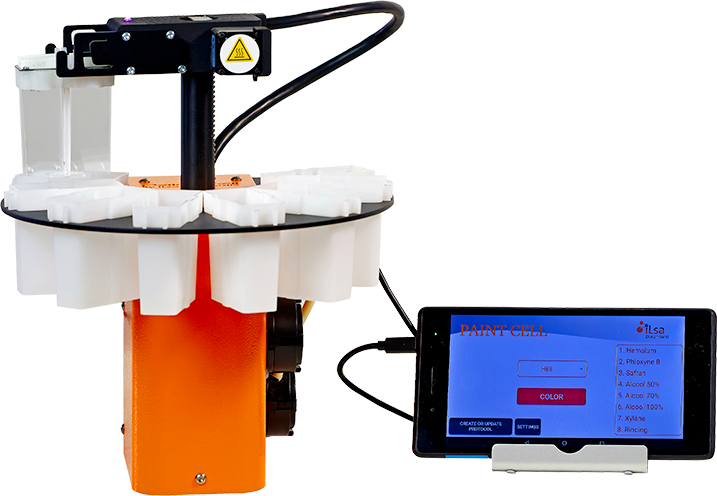

Le Paint Cell est conçu pour automatiser les colorations spéciales, chronophages, réalisées manuellement dans vos laboratoires.

Agitateur pour pots de prélèvement qui permet de dissocier les amas de cellules et de dissoudre les mucosités sources de défaut d’étalement par une agitation verticale

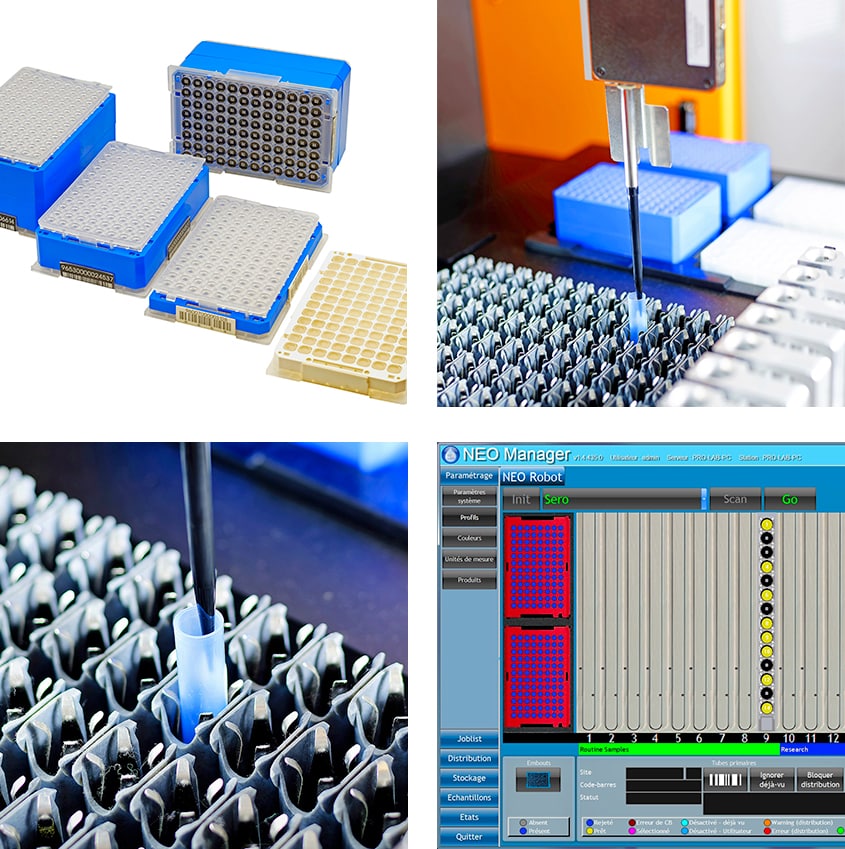

L’originalité du système 3S (Safe Sampling Systems) : c’est sa microplaque brevetée.

C’est une microplaque monobloc constituée de puits sécables. La microplaque est identifiée avec un numéro unique imprimé en usine (code à barres) et chaque puits est aussi identifié avec ce même numéro auquel est ajouté sa position sur la microplaque (DataMatrix). Chaque puits a donc une identification unique, cette configuration originale simplifie la gestion de votre sérothèque.

L’utilisation d’embouts jetables et capacitifs permet d’éviter toute contamination et la vérification du volume aliquoté. Sa barrière anti-intrusion, son MTBF et son prélèvement intelligent font de cet automate un appareil fiable et robuste. La gestion des tubes primaires et microplaques par codes à barres, des puits par DataMatrix permettent d’éviter toute erreur humaine.

L’automate devient un maillon essentiel pour l’accréditation de votre laboratoire car il prend en charge en toute sécurité sans erreur possible la totalité de la gestion de votre sérothèque.

L’originalité du système 3S : C’est sa microplaque monobloc brevetée constituée de puits sécables.

PARIS

7 Chemin de Saint-Hilaire

95310 SAINT-OUEN-L’AUMÔNE - FRANCE

Tél : +33(0)1 34 30 42 00